- Home

- About Us

- Products

- Contact

Products

Portable Rockwell Hardness Testing Machine

Rate:We make available highly efficient Portable Rockwell Hardness Testing Machine to the length and breadth of the country for conducting tests by the means of the universally acknowledged hardness testing method. We are reputed to be among the reliable Manufacturer and Supplier of Portable Rockwell Hardness Testing Machine in Maharashtra. It is appreciated for its light weight and accurate results. And it is offered in a wide range of specifications.

Method of Test :

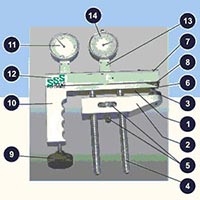

- Select proper penetrator (6) depending upon the material to be tested.

- Take precaution so thet the penetrator does not project beyond the Upper clamp (1). For this, the loading screw (9) should be sufficiently taken back.

- Place the test specimen securely on suitable anvil (3).

- Clamp test specimen firmly between upper clamp (1) and support anvil (3) by rotating the knurled knob (5) on the lower clamp (2). Do Not Apply Extra Pressure.

- Check Zero Setting Load Indicator (11). Rotate Bezel to Bring Pointer Over Small Black Dot for Zero Load.

- Apply 10 kgf (98.07 N). major load by rotating the load screw (9) in clockwise direction such that the pointer on the load indentor (11) comes on set position. Check zero setting of penetrator indicator (14). Rotate bezel to bring pointer to 'O' on the black scale.

- For 'C' scale use diamond penetrator against load of 150 kgf (1471 N) and for 'A' scale use same diamond penetrator against a load of 60 kgf (588.4 N). For 'B' scale use 1/16 ball penetrator against a load of 100 kgf (980.7 N).

- Take off major load by turning the loading screw in anticlockwise direction, such that only minor load of 10 kgf. (98.07) remains in action-(pointer back to 'set' position).

- Hardness value in Rockwell scale is directly indicated on the penetrator indicator (14). Read of number on black scale is diamond penetrator. Read off number on red scale is ball penetrator

- Release load completely by taking back the loading screw (9).

- Turn the knurled knob (5) in anticlockwise direction to loosen clamp and thus the test speciman.

Technical Specifications of Rockwell Hardness Testers

| Maximum test height | 110 mm |

| Throat capacity | 55mm |

| Flat Anvil | 1 No. |

| V' Anvil | 1 No. |

| Test Blocks | 2 Nos. |

| Diamond Penetrator | 1 No. |

| 1/16" Ball penetrator | 1 No. |